Self-Powered Plus offers the highest availability in the market

We have reinvented the self-powered technology with an upgraded solution to increase the solar production availability while reducing CAPEX and simplifying installation.

Self-Powered Plus with smart power system

When the inverter is operating, the TCU obtains power from the string (with a negligible effect on inverter production). But when the string is open (due to inverter maintenance or fault, or even before the inverter has been commissioned), the TCU will seamlessly switch to obtain power from one PV module in the tracker.

Self-Powered Plus allows continuous power availability for the TCU, from the same day the PV modules are installed, while freeing up space on the tracker surface.

Furthermore, when irradiance is very low, the TCU is still able to obtain the energy needed to keep the system in optimal conditions, due to the much higher power available from the string or single PV module, when compared with traditional self-powered configurations with a pony panel.

And in the event of any failure, the TCU includes an internal fail-safe protection that will bypass its input, allowing uninterrupted inverter operation.

Avoid inverter input over-voltage lockouts

PV inverters can fail to start after a maintenance stop or disconnect, due to an input over-voltage condition, if the trackers are pointing at the Sun with very high irradiance and very low temperature.

When this happens, production is lost until the trackers are manually defocused and the inverter is then restarted.

By monitoring the string current, a SPP tracker controller can detect if the inverter is off, and then defocus the tracker automatically so that the string output is reduced below the over-voltage threshold.

Eventually, as soon as the inverter is rearmed, current will start flowing through the string, and the controller will immediately refocus the tracker to achieve peak production.

Self-Powered Plus and the inverter cooperate seamlessly

In the event of a string disconnection (due to inverter failure or maintenance), the TCU will not be affected, providing a significant advantage during plant operation – even during the commissioning phase, before the string has been wired.

The TCU consumption is negligible, with an intermittent power demand of up to 30W, resulting in a typical energy consumption of less than 0.02% of the tracker production throughout the year.

An easier setup and cost-effective

Self-Powered Plus (SPP) uses the same footprint as the standard Self-Powered TCU but with a simplified setup - that reduces CAPEX - as a pony-panel is not required.

Additionally, maintenance costs decrease significantly, particularly during the cleaning process.

Availability on the darkest and cloudiest days? Yes.

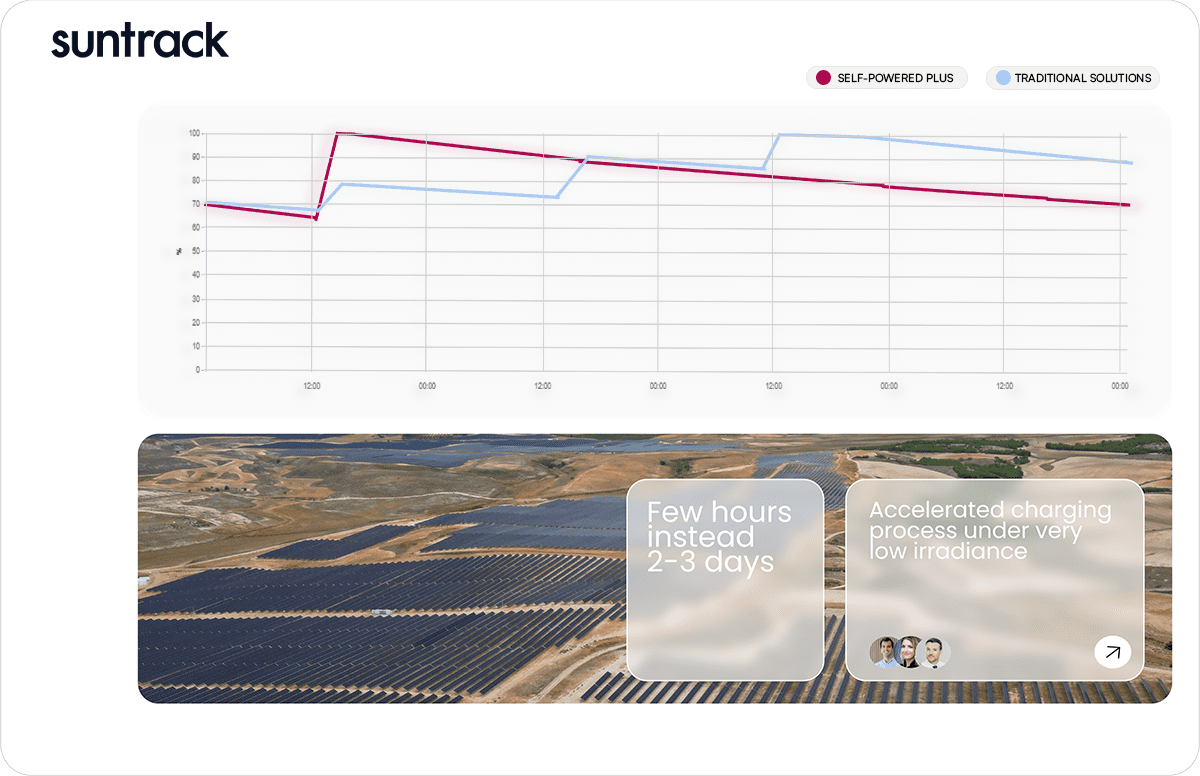

The Self-Powered Plus solution obtains a 30W steady power supply vs the theoretical 60W peak available from the dedicated panel in traditional solutions.

This stable availability of power allows a notably

accelerated charging process under conditions of very low irradiance, resulting in a fully-charged battery within a few hours, in contrast to the slow charging times (2-3 days) observed in alternative solutions.

More availability

The SPP (Self-Powered Plus) system will always be able to move the tracker and recharge the battery, avoiding stow periods due to critical battery alarms, therefore increasing overall energy production.

100% made in the USA

100% produced in the USA, eliminating the need for importing the pony-panel. Self-Powered Plus is the best and most reliable solution for the U.S. market as it aligns with the requirements of the Inflation Reduction Act.

Boosting the aftermarket

Self-Powered Converter (SPC) is specifically developed as an aftermarket solution for plants with undersized traditional self-powered systems – panel and / or battery size too small for the irradiance conditions of the specific location.

Based on the same power system featured in the SPP controller, this module can replace the dedicated PV panel, increasing the primary power available for the TCU to move the tracker and recharge the battery in heavily cloudy days.

As a result the TCUs will not have their batteries drained during long overcast periods, increasing the overall availability of the trackers and consequently the production of the plant.

🇪🇺 HQ Europe · Production Plant

Virgen de la Guía 19, 48810, Alonsotegi, Vizcaya (Spain)

Phone: (+34) 94 498 2028

🇺🇸 P4Q USA, INC. · Production Plant

5901 Office Blvd., Albuquerque, NM 87109, (USA)

Phone: + 1 50 5341 9179

🇨🇳 PFQ China · Production Plant

No.88, Hongyang Road, Qiandeng Town, Kunshan City, Jiangsu Province, Building Q

Phone: 0512-36882626

© 2024 P4Q. All rights reserved · Legal Warning and Privacy Policy · Cookies Policy